Description

Labeled Mylar Bags Wholesale for Food and Retail Brands

Labeled Mylar bags help products ship safely, stay fresh, and get noticed on the shelf. This page covers Labeled mylar bags wholesale, printing choices, size options, and smart buying tips. At Premium Mylar Bags, we make custom runs fast, consistent, and budget friendly. You get short sentences, clear choices, and real answers to what matters when you are ordering packaging.

Cool Mylar Bags are a popular style customers pair with labels for seasonal drops and small-batch launches. If you want a bolder look, you can reference that page as you plan the artwork and the label area on your current order.

Built for clarity branding and food safety

A labeled pouch needs clean surfaces, true color, and a finish that takes adhesive well. Our films are chosen for print accuracy and seal strength. You get consistent zipper feel, tear-notch placement, and heat-seal behavior that keeps fulfillment lines moving.

How labeling adds value

- Lets you run one base design, then apply small label changes per flavor or strain.

- Speeds launches because labels print faster than full pouch reprints.

- Keeps compliance current when rules change in different regions.

- Reduces leftover inventory by shifting SKUs with labels instead of full reprints.

Film choices explained

- PET with aluminum barrier for long shelf life.

- PET with clear window when visibility helps sales.

- PET Kraft laminate for a natural look with modern barrier.

- Recyclable options available on request.

Labeled mylar bags cheap guide to smart buying

Budgets matter. You want a labeled pouch that looks clean without pushing cost per unit too high. The simplest path is to use one common base pouch and change only the label for each flavor or size.

Ways to save without losing quality

- Choose one or two standard pouch sizes across your line.

- Print base art in bulk, then apply labels by SKU.

- Keep label sizes uniform to speed application.

- Use matte laminate on labels to hide minor scuffs during shipping.

- Confirm barcode size and contrast during proofing to avoid rescans.

When full print is better than labels

- Very large runs where unit cost drops sharply.

- Artwork that wraps across the whole pouch face.

- Premium retail doors that expect edge-to-edge print.

| Pouch format | Best use | Closure style | Label placement ideas |

|---|---|---|---|

| Stand-up with zipper | Snacks, coffee, tea, gummies | Press-to-close zipper + heat seal | Center front brand label + small nutrition label on back |

| Flat pouch | Samples, single-serve, kits | Heat seal only | Corner flavor label + back batch label |

| Window pouch | Dried fruit, trail mix | Zipper + seal | Slim vertical label alongside window |

| Kraft laminate | Grounds, herbs, dry blends | Zipper + seal | Wider front label for high contrast on Kraft |

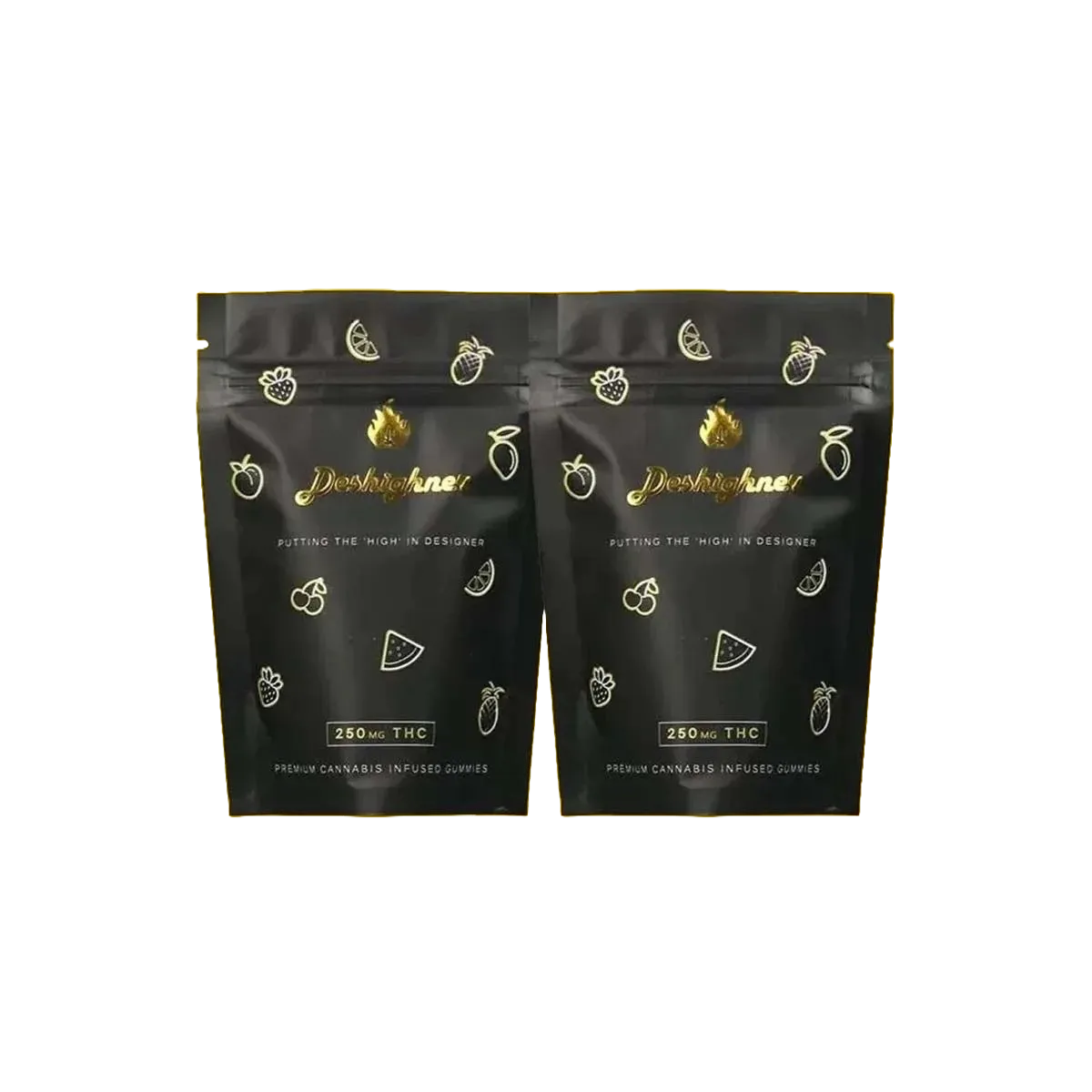

| Child-resistant | Regulated items | Certified CR zipper | Compliance label near zipper + strain or flavor label front |

Clear faces benefit from smaller labels to keep product visible. Opaque films give you room to place larger labels without visual conflict.

Printing and finish options for labels and pouches

Printing quality plays a major role in how your labels and pouches represent your brand. Decorative Mylar Bags enhance this presentation by pairing strong barrier protection with premium print clarity. High-definition printing ensures sharp text, vivid colors, and clear graphics that attract customer attention. Most manufacturers use CMYK digital or offset printing for vibrant imagery, while PMS color matching helps maintain consistency across product lines. You can also add metallic inks, holographic foils, or white ink layers for extra visual depth and luxury appeal.

| Method | Best for | Durability notes | Finish look |

|---|---|---|---|

| Digital CMYK | Fast art changes, many SKUs | Good for short runs | Smooth color gradients |

| Spot color | Brand-critical Pantones | Highest match accuracy | Solid, repeatable blocks |

| Metallic foil | Premium cues | Add lamination to protect | Reflective highlights |

| Matte laminate | Fingerprint control | Hides light scuffs | Soft, low glare |

| Gloss laminate | Shelf pop | Wipe-clean surface | Bright and crisp |

What to check before you approve your proof

A fast checklist prevents relabeling or returns later. Keep these points in mind during review.

Brand and compliance details

- Check barcode quiet zones and scan at two angles.

- Confirm net weight text height meets your market rules.

- Place contact info and batch code in the same spot every SKU.

- Test a real heat seal with your filling temperature.

- Verify zipper alignment so labels do not cross seams.

Mylar Bag Strain Labels and flavor systems

- Use a color system tied to flavors or strains.

- Keep a shared label backbone so only color and text change.

- Reserve one area for quick-drop seasonal runs.

| Feature | Details | Material Options | Finishing Choices | Add-ons & Features | Usage/Application |

|---|---|---|---|---|---|

| Qty Range (100–1,000) | Small production batches | Standard paper stock | Basic finish | Small batch support | Best for pilots and local launches |

| Qty Range (1,000–5,000) | Moderate volume runs | Corrugated, Kraft | Gloss or Matte | Volume efficiency | Suitable for expanding restaurants and bakeries |

| Qty Range (5,000–20,000) | Medium-scale manufacturing | Recycled paper or kraft options | Spot UV or smooth matte | Spare labels or inserts | Ideal for regional supply and steady orders |

| Qty Range (20,000+) | Large-scale bulk orders | All board types | Premium finish options | Locked artwork and scalable SKUs | Designed for national distribution and chain outlets |

| Lead Times | 6–15 business days based on order size | Various stock grades available | Smooth or coated finish | Rush service available | Perfect for urgent or scheduled packaging needs |

| Notes | Cost efficiency improves with volume | Eco-friendly choices | Consistent quality across sizes | Design support and brand consistency | Best for both startups and established enterprises |

Price varies with size, laminate, zipper, artwork coverage, and label stock. Ask for a split across two sizes if you plan both samples and retail bags.

Mylar bag sticker printer options at a glance

If you apply labels in-house, the printer choice matters. Think in terms of colorfastness, speed, and resistance to oil or moisture.

Common paths

- Inkjet with pigment inks for rich color and good water resistance.

- Thermal transfer for high-durability barcodes and batch codes.

- Laser labels for crisp text on matte stocks.

Tips for clean label application

- Wipe pouch face to remove dust before applying.

- Use alignment jigs for fast repeat placement.

- Apply labels after sealing to avoid heat lift.

- Store label rolls in a cool, dry place.

Sizing and fill guidance

Choose sizes based on net content and target shelf shape. Leave enough headspace for a reliable seal and a straight, bubble-free label.

| Net content | Suggested face width | Approx. height | Notes |

|---|---|---|---|

| 14–28 g samples | 3–4 in | 5–6 in | Flat pouches reduce material use |

| 100–150 g | 5–6 in | 8–9 in | Good for small stand-ups |

| 250–350 g | 6–7 in | 9–10 in | Standard shelf footprint |

| 500 g–1 kg | 7–9 in | 11–13 in | Add bottom gusset support |

Keep the label at least 0.25 in from any fold or heat seam to avoid peeling. For cold rooms, choose a freezer-grade adhesive.

Custom printed Mylar bags no minimum versus bulk strategies

Small brands often ask if they can start with very small runs. Yes, Custom printed Mylar bags no minimum options exist for tests, but unit cost is higher. When you are confident in the recipe and artwork, step into Labeled mylar bags bulk to reduce cost per unit and stabilize films and seals across SKUs.

When to move from pilot to bulk

- Sell-through is stable for three consecutive weeks.

- Compliance text and icon set have no changes pending.

- Retailers confirm fit on shelves and pegs.

- Reorder lead time is inside your planning window.

Workflow ideas for growing teams

Labels can be printed centrally and shipped to co-packers with clear placement instructions. Use a one-page art guide with rulers and photos. Standardize on one label width across SKUs, then vary height slightly for long names.

Teams that rely on Premium Mylar Bags also benefit from consistent quality and up-to-date packaging options. This helps streamline workflows, reduces delays, and ensures your product line maintains a professional and reliable presentation.

How to keep labels readable after filling

Heat, oil, and handling can blur ink or lift corners. Match label stock to real-world conditions.

Simple steps

- Choose matte laminate when bags stack tightly in cartons.

- Round label corners to reduce edge catch.

- Add a light varnish for extra scuff resistance.

- For clear-window pouches, use translucent labels sparingly so product remains visible.

Labeled mylar bags for sale with compliance in mind

Regulated products require space for warnings and batch data. Plan your layout early so labels fit without covering zippers or windows.

Layout notes

- Put warnings on the back above the bottom fold.

- Keep flavor text separate from nutrition or compliance blocks.

- Use 100% black for barcodes to keep scans clean.

- Print date and lot code with thermal transfer on a blank area.

Custom Mylar bags wholesale with steady color and seals

Wholesale runs should carry consistent film, laminate, and zipper sources. That keeps label adhesion the same across months of orders. Lock your art files and naming conventions so relabeling for new flavors is simple.

What we standardize

- Film families and laminate thickness

- Zipper brand and notch spacing

- Inside varnish when needed for oil resistance

- Box counts for easy receiving and cycle counts